Heavy Duty Shelves: Ultimate Guide for Industrial Warehouses

In the demanding world of industrial warehousing, heavy duty shelves are not just a convenience—they're a necessity. Designed to support large volumes, high weights, and tough operating conditions, heavy duty shelving systems form the structural backbone of modern logistics, manufacturing, and wholesale operations.

The primary characteristic of heavy duty shelves is their exceptional load capacity. Individual shelves can typically support 800 to over 3000 kilograms, depending on the material, design, and reinforcements. This allows for the safe storage of machinery parts, bulk products, metal components, and palletized goods, making them ideal for factories, distribution centers, and supply depots.

These shelves are commonly made from thick-gauge rolled steel with anti-corrosion coatings or galvanization. Their robust construction ensures not only long-term performance under heavy stress but also protection from environmental factors such as moisture, dust, and temperature changes.

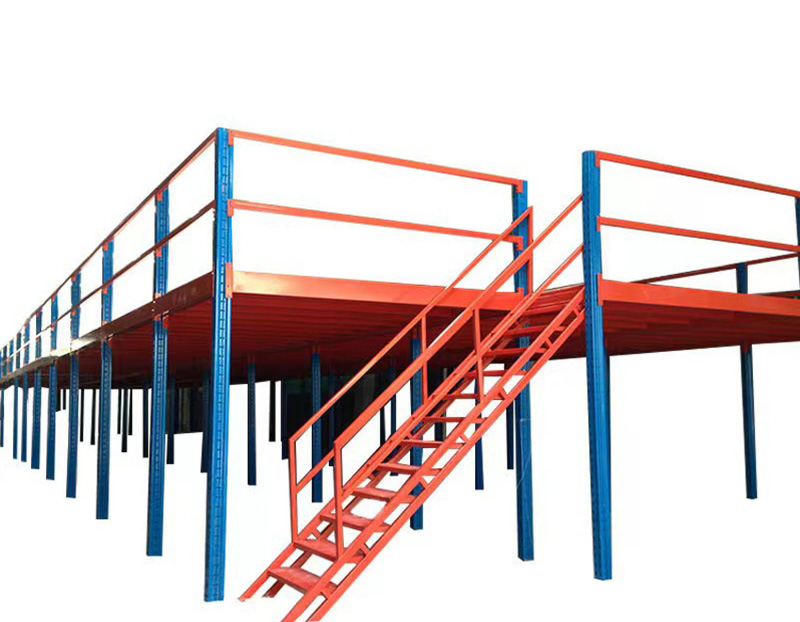

Another major benefit of heavy duty shelves is their customizability. Many systems come with adjustable beams and can be configured as selective racks, drive-in racks, cantilever systems, or mezzanine platforms depending on operational needs. This makes it easy to adapt the shelving layout as the business grows or inventory changes.

Safety is a critical concern in industrial environments, and heavy duty shelving systems are built to comply with strict load-bearing and seismic standards. Features such as welded joints, locking pins, footplates, and anchor bolts help prevent tipping, shifting, or structural failure during daily use or emergency situations like earthquakes.

While initial investment in heavy duty shelving may be higher than lighter alternatives, the long-term benefits far outweigh the cost. Their durability means fewer replacements, reduced downtime, and improved overall efficiency in material handling operations. Moreover, they contribute to optimized space utilization by enabling high stacking, thus reducing the need for additional floor space.

Installation of these systems typically requires professional assembly, especially for multi-tier or high-rise configurations. However, once in place, they offer a scalable and high-performance storage infrastructure that can serve an operation for decades with minimal maintenance.

In summary, heavy duty shelves are essential for any warehouse that deals with large, heavy, or high-volume goods. Their strength, reliability, and adaptability make them a smart investment for improving safety, space management, and operational flow in industrial settings.

Smart Storage Equipment: Top B

Smart Storage Equipment: Top B

Storage Systems: Design Ideas

Storage Systems: Design Ideas

Storage Systems: Best Software

Storage Systems: Best Software

Storage Systems: Maximizing Sp

Storage Systems: Maximizing Sp