Storage Systems: How to Build a Modular Warehouse

Building a modular warehouse storage system offers flexibility, scalability, and cost-efficiency—key benefits for businesses facing changing inventory needs and evolving workflows. Modular warehouses are designed using standardized components that can be assembled, reconfigured, and expanded with minimal disruption.

Start by assessing your storage requirements: inventory types, throughput rates, space constraints, and future growth plans. This analysis guides the selection of appropriate modular components such as shelving units, pallet racks, mezzanines, and automated systems.

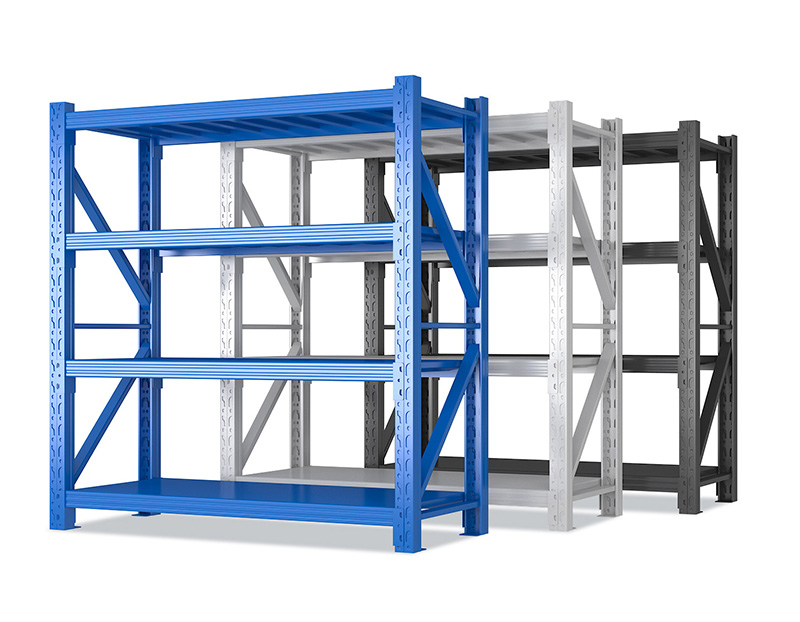

Choose modular shelving and racking systems made of durable materials like steel, with adjustable fixtures and beams. These allow easy resizing to accommodate products of varying sizes and weights. Boltless or clip-in designs speed up installation and rearrangement.

Incorporate mobile shelving or compact storage systems where space is limited. These units slide on tracks, reducing aisle widths and maximizing storage density without sacrificing accessibility.

Plan for vertical expansion by adding mezzanine floors. Modular mezzanines increase usable floor space without costly building extensions. Ensure structural components support the intended load and comply with safety regulations.

Integrate smart storage equipment such as automated guided vehicles (AGVs), conveyors, or robotic picking systems for improved efficiency. These technologies can be added incrementally as budget and needs evolve.

Create clear labeling, signage, and digital inventory tracking to maintain order as the system scales. Modular warehouses benefit from adaptable workflows supported by flexible layouts and real-time data.

Finally, consider future adaptability. The hallmark of modular design is the ability to adjust the storage layout without major renovations. This flexibility helps businesses respond quickly to market demands, seasonal fluctuations, or product changes.

In summary, building a modular warehouse requires thoughtful planning, selecting versatile components, and prioritizing scalability. The result is a cost-effective, efficient storage system tailored to your current and future needs.

Estanterías ligeras: las mejores ventajas para espacios de a

Estanterías ligeras: las mejores ventajas para espacios de a

Estanterías medianas: perfecto equilibrio de resistencia y f

Estanterías medianas: perfecto equilibrio de resistencia y f

Heavy Duty shelf: Ultimate Guide for Industrial warehouse (e

Heavy Duty shelf: Ultimate Guide for Industrial warehouse (e

Tendencias en equipos de almacenamiento inteligentes que tra

Tendencias en equipos de almacenamiento inteligentes que tra