Heavy Duty Shelves: Comparing Welded vs. Bolted Designs

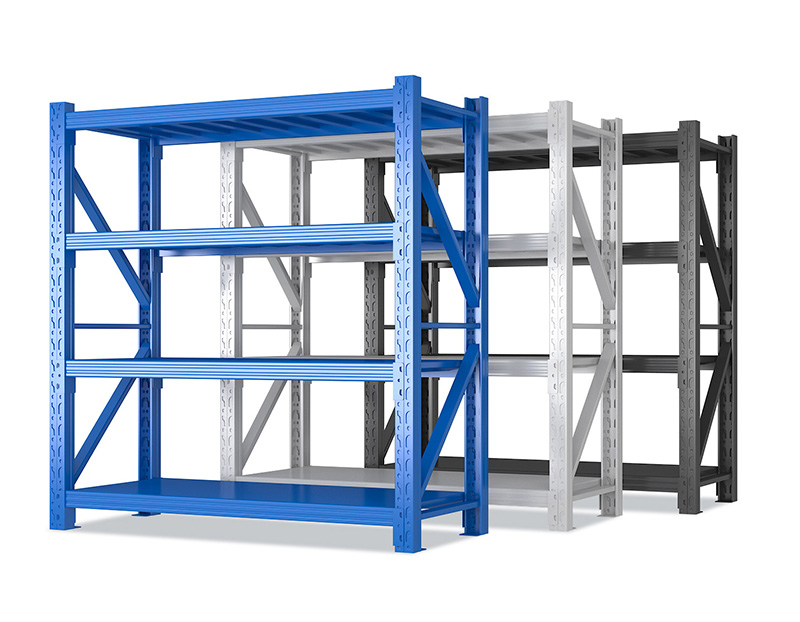

When choosing heavy duty shelving systems, one important decision is whether to go with welded or bolted designs. Both offer substantial strength and durability, but they differ in terms of structure, installation, flexibility, and long-term performance.

Welded fixtures are manufactured as a single, pre-assembled frame. This type of shelving provides superior rigidity and is less likely to shift or loosen under heavy loads. Because the joints are fused together with high heat, welded fixtures are extremely stable, making them ideal for seismic zones or high-traffic warehouses where maximum safety is a priority.

On the other hand, bolted fixtures come in kits and are assembled on-site using bolts, nuts, or fasteners. While they may take slightly more time to install, they offer flexibility in customization. Businesses can adjust shelf heights or disassemble and reconfigure the unit later as storage needs change. This modularity is particularly useful for growing operations or facilities with evolving inventory profiles.

From a cost perspective, bolted designs are typically more affordable up front and easier to transport due to their flat-pack shipping format. Welded units, by contrast, take up more space in transit but save labor costs during installation because no assembly is required.

Maintenance is another factor to consider. Welded shelving generally requires less upkeep since there are no bolts to loosen. However, if a welded unit is damaged, repair options are limited and often require welding equipment. Bolted systems are easier to repair or replace component parts without professional tools.

In summary, welded fixtures are best suited for permanent, high-capacity installations where strength and rigidity are critical. Bolted fixtures, on the other hand, offer more adaptability and cost-efficiency. The right choice depends on your operational needs, budget, and whether you prioritize stability or flexibility.

Estanterías ligeras: las mejores ventajas para espacios de a

Estanterías ligeras: las mejores ventajas para espacios de a

Estanterías medianas: perfecto equilibrio de resistencia y f

Estanterías medianas: perfecto equilibrio de resistencia y f

Heavy Duty shelf: Ultimate Guide for Industrial warehouse (e

Heavy Duty shelf: Ultimate Guide for Industrial warehouse (e

Tendencias en equipos de almacenamiento inteligentes que tra

Tendencias en equipos de almacenamiento inteligentes que tra